A Material Solution for the Train Journeys of Tomorrow

INTRO

After 50 years of providing the highest quality of film laminated metals to the marine industry Metalcolour announces its presence to the world of trains. Dobel F105 Film Laminated Aluminium could not be better suited to the design and manufacture of tomorrow’s train interiors.

Extensively tested and fully approved to meet the highest fire safety standards according to EN 45545 HL3, the sheets can be processed in as many ways that you can think of. With over 400 colours, textures, patterns and designs on stock, and over 1000 on request, the only limits are your imagination.

Dobel F105 sheeting is extremely durable, containing an additional protection layer against scratches and detergents ensuring the interiors stay as beautiful as they are intended to. The product is very light and easy to form, making it highly suitable for use within train interiors.

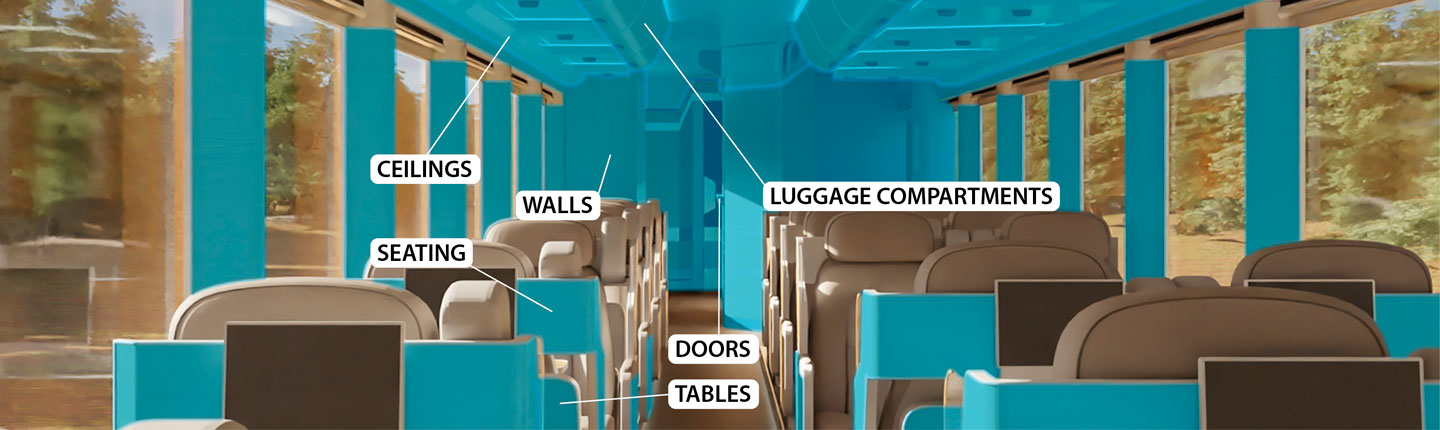

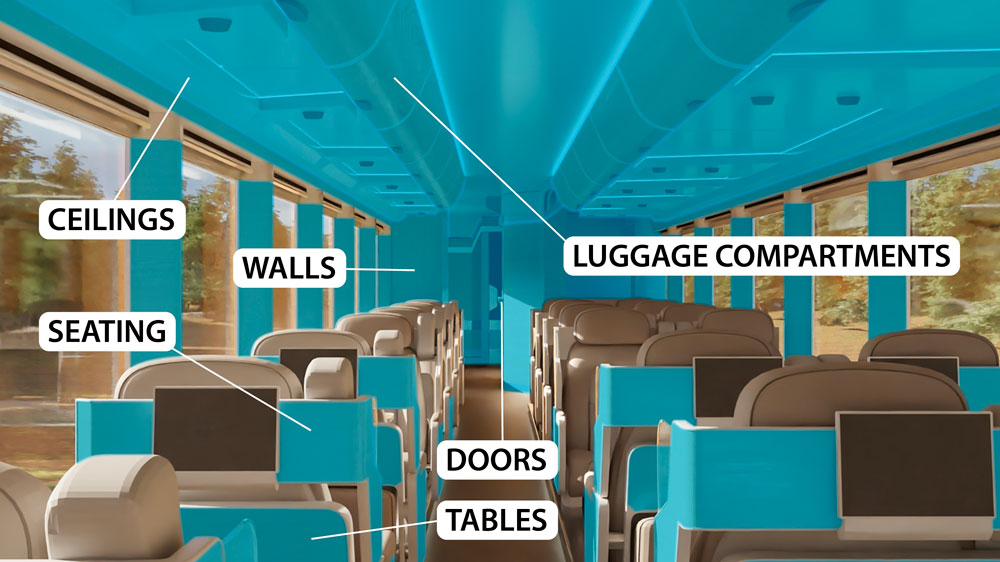

Consider the applications. Of course there are walls and ceilings but Metalcolour sees huge potential in seating, tables, acoustic solutions, doors, the list goes on and on. We want to inspire innovative solutions to design challenges.

Dobel Film Laminated Aluminium offers designers the freedom to express themselves and to create unique environments for the train journeys of the future.

MANUFACTURING

All our DOBEL products are made in Sweden. Scandinavian manufacturing standards are some of the highest in the world and we are proud to be part of that tradition. We strive towards more sustainable material supply solutions and we currently use aluminium with a minimum 40% recycled material. This is set to rise in the future as we continue to lower our CO2 impact.

We only purchase fossil-free electricity and use river water instead of drinking water in our cooling processes. This water returns to the river with no impact to the river’s health. Our unique production process leads to notable weight savings per square meter, lowering the energy output of the entire train.

We believe in the sustainability of highly durable products that perform extremely well over a long period when subjected to daily wear and tear and regular cleaning.

By delivering a pre-laminated aluminium sheet with a scratch-resistant coating we remove several complex production phases. This makes repair, replacement and re-coating far simpler and more cost-effective.

The design trend towards natural materials continues to grow as travelers appreciate more and more the warmth and sense that wood provides. Traditional plywood laminates are heavy, difficult to produce and remain sensitive to damage.

Dobel sets out to replace older manufacturing methods with new, more efficient techniques. These changes result in the reduction of lead-times, buying-stages and have a significant effect on lowering the cost.

For example, honeycomb structures are widely used for their lightness and strength. They are often delivered with blank aluminium sheets, onto which the decorative layer is applied at a later date. Dobel F105 laminated aluminium replaces the need for the application of a separate decorative layer reducing costs and production time and the weight all at the same time.

AESTHETICS

Shifts in modern mass transport require creative solutions for space and aesthetics as customers desire an inviting, comfortable and flexible passenger environment.

One of the many stand-out characteristics of Dobel F105 is the ability to form, profile and shape with no distortion of the print, colour or pattern. The structures remain consistent and the potential application almost limitless.

Reconsider the restrictions of using traditional methods and open your imagination to new possibilities.

The flexibility of pre-laminated aluminium is another stand-out feature. The sheeting lends itself naturally to walls and doors but it doesn’t stop at that. Because it can be easily rolled, pressed, profiled and formed, designers can find simple solutions to complex problems found with traditional hard laminates.

A simple process that could take months of testing and development in wood will take seconds with Dobel F105. We call this “Shapeability” and we invite you to discover what is possible with our laminated aluminium.

Alongside wood designs we have different types of stone, metals and textiles in both vertical and horizontal. Our prints only repeat up to 2.5 meters ensuring a natural feel to longer applications of the sheets. We have 72 different options in our standard collection, 400 in stock and well over 1000 others available on request. This number is growing by the week and we look forward to being challenged by your creativity.

We have over 50 years experience working with coated metals and our design support team are confident in dealing with all kinds of requests. Over the years we have learned that access to real product samples is crucial to a productive collaboration and we have established routines for getting samples into your hands as quickly as possible. We can send anything as small as a few centimeters to several meters squared, just get in touch and we’ll help you out.

SUMMARY

So, to sum up – Safety comes first. We have invested extensively in developing a safe product that can be used freely with peace of mind.

We believe that a sustainable product is a durable product. Our laminated aluminium can withstand daily wear and tear over many years which also makes it a sound investment.

Our sheeting will be built into spaces that move. Because it is so light, less energy will be wasted moving it around which is a positive step for both operators and passengers.

DOBEL Film Laminated Aluminium has Shapeability! It is easy to process and pre-lamination significantly reduces several phases of production.

Our prints, patterns and colours are beautiful. We offer a huge range of natural effects whereby the only limits are the designer’s imagination. Inspiring Innovation.

CONTACT

Please reach out to our train interior experts Per Nord (Western Europe and Americas) or Marcin Parczewski (Central and East Europe): https://metalcolour.com/contact-us/