Streamline your production with Metalcolour Technical Coating

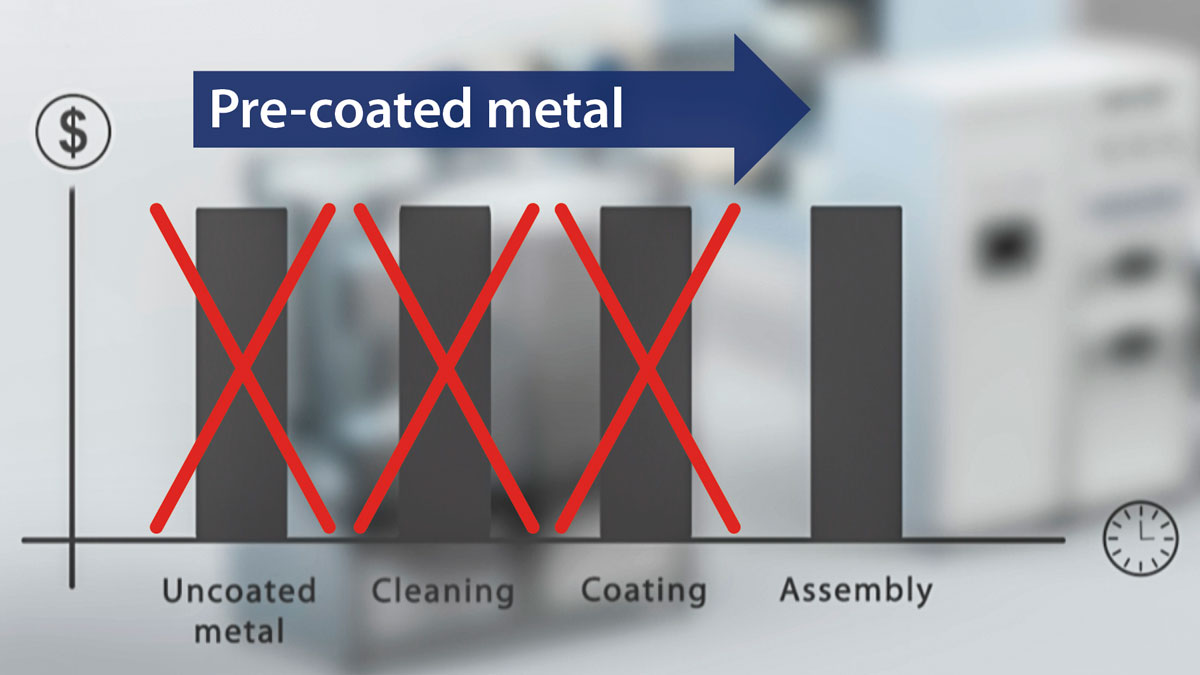

When there is a need for coated metal with different types of coating for different functional or technical purposes. This can be to increase or decrease friction, reduce noise or vibration, protect against corrosion or bond metal with other materials like rubber and plastics. This part of the manufacturing process is often done at our customers own production plant. By using pre-coated metal instead, there is great potential to reduce the number of steps in the overall manufacturing process and thus save both time and costs.Where is Metalcolour Technical coating used?

When it comes to Metalcolour Technical Coating, it is not always a predefined product. We have often, in collaboration with the client and suppliers, developed and adapted a solution to match functions specific to the customer’s needs. Among other things, we have developed solutions for various parts in the automotive industry, parts for white goods and for safety shoes. There are also sustainability perspectives and environmental perspectives worth mentioning. Our production is certified, which means that we have full control and traceability in our production. The manufacturing plant is optimized for this type of production and all components are approved according to end-users’ requirements. The number of residual products is minimized and handled in a secure manner. We, at Metalcolour, see great opportunities to help our potential clients by providing them with a new standard. The streamlining through the transition to pre-coated metal and the benefits it adds, gives manufacturers the opportunity to increase their competitiveness.

When using pre-coated metal you save a lot of costly steps in the overall manufacturing process which saves both time and costs.

Metalcolour Technical Coating is a highly specialized product range offering customized solutions in coil coating of numerous metal substrates with own developed or customer specified coatings, primers and binders. The solutions developed typically have several purposes in a combination of technical requirements and high-volume production. Main part of our clients utilizes Metalcolour to industrialize processes to take advantage of economies of scale in decreasing cost per unit. Great savings has been generated by solutions from Metalcolour Technical Coating. Applications include Noise & Vibration Dampening, Anti-Friction, Temperature Resistance, Anti-Galvanic Corrosion, Resistance to Chemicals & Oils, Sealing & Gaskets, UV resistance, Welding and Soldering. Metalcolour have three factories around the globe. Our factory in Denmark specializes in pre-coated and pre-painted steel, Stainless steel and aluminum. Read more about Metalcolour at metalcolour.com or learn more about Metalcolour Technical Coating in this video: Ronnie Skov, Commercial ManagerWhy Metalcolour should be your partner in the conversion

What are the benefits?

https://metalcolour.com/technical-coating/For further information contact:

rs@metalcolour.com | +45 4028 8002